Benefits of Implementing IMS in Power Plants

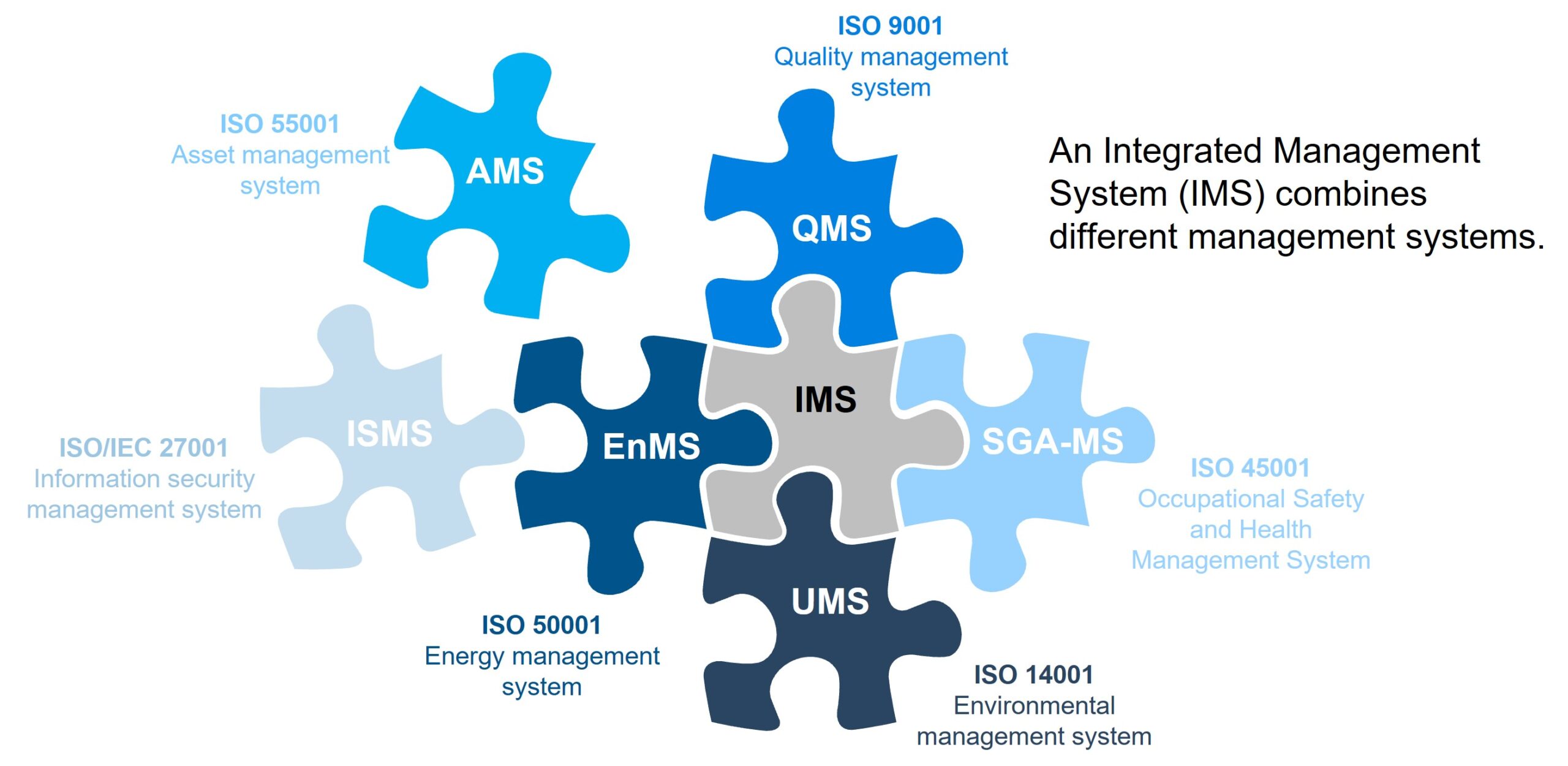

The benefits of implementing IMS in power plants—specifically by integrating ISO 9001, ISO 14001, and ISO 45001—are extensive and critical in today’s energy sector. An Integrated Management System (IMS) merges quality, environmental, and occupational health and safety standards into one streamlined framework. For power plants, where safety, sustainability, and operational efficiency are paramount, this unified approach delivers measurable value.

1. Enhanced Operational Efficiency

Implementing ISO 9001 as part of an IMS ensures a consistent and process-driven approach to quality management. Power plants often involve complex workflows with high regulatory compliance. Standardizing these through IMS:

- Minimizes process variation

- Enhances coordination between departments

- Reduces downtime and maintenance errors

- Improves reliability and consistency in energy generation

2. Improved Health and Safety Culture

ISO 45001, the global standard for occupational health and safety (OH&S), is crucial for power plant operations where high-risk activities are routine. When integrated through IMS, this standard:

- Promotes proactive hazard identification and risk management

- Reduces workplace incidents and near misses

- Ensures legal compliance with OH&S regulations

- Increases employee confidence and morale

A strong safety culture not only saves lives but also improves plant productivity and public reputation.

3. Environmental Compliance and Sustainability

ISO 14001 focuses on environmental management. Power plants, particularly thermal and fossil-fuel-based units, significantly impact the environment. With ISO 14001 as part of the IMS:

- Plants reduce emissions, waste, and energy consumption

- Environmental impact assessments become standard practice

- Regulatory audits are simplified and passed more easily

- Stakeholder trust in environmental responsibility increases

This is especially valuable in regions where environmental licensing and monitoring are strict.

4. Cost Reduction and Waste Minimization

By integrating quality, safety, and environmental management, power plants can streamline operations and eliminate redundancies. IMS reduces:

- Duplicate documentation and audits

- Training time and administrative overhead

- Non-compliance penalties

- Material and energy waste

This ultimately leads to substantial cost savings and optimized resource allocation.

5. Stronger Regulatory and Legal Compliance

IMS supports a structured approach to meeting legal and regulatory requirements. With ISO 9001, ISO 14001, and ISO 45001 working in synergy:

- Compliance data is centralized and easy to access

- Internal audits become more effective

- Legal risks are minimized

- Certification improves tender eligibility and investor confidence

“Power plants across Pakistan are increasingly adopting IMS standards like ISO 9001, ISO 14001, and ISO 45001 to enhance operational efficiency, ensure environmental compliance, and improve workplace safety.”

6. Continuous Improvement Culture

The PDCA (Plan-Do-Check-Act) cycle, a core component across all ISO standards, drives continuous improvement across operations. Power plants using IMS:

- Regularly analyze performance data

- Identify and address root causes of issues

- Engage employees in performance feedback loops

- Maintain agility in a dynamic energy market

Conclusion

Final Thoughts: A Strategic Move Toward Excellence

The integration of ISO 9001, ISO 14001, and ISO 45001 under an Integrated Management System (IMS) isn’t just a regulatory checkbox — it’s a strategic investment in operational excellence. For power plants, this move results in optimized workflows, improved environmental stewardship, and an uncompromising approach to health and safety.

Beyond compliance, IMS fosters a culture of continuous improvement. It empowers leadership and employees to take ownership of quality, safety, and sustainability — ensuring that these values are embedded across departments. This holistic framework not only reduces risks and improves incident response, but also enhances the plant’s reputation among stakeholders and the public.

Moreover, the global energy sector is under increasing pressure to align with ESG (Environmental, Social, and Governance) goals. Adopting IMS standards positions power plants to meet future regulatory requirements and international benchmarks while reinforcing stakeholder trust.

In conclusion, implementing ISO 9001, 14001, and 45001 through IMS at power plants is not just about ticking boxes — it’s about building smarter, safer, and more sustainable energy infrastructures that will stand the test of time.

Benefits of Implementing IMS in Power Plants