Introduction: Why Implement an Integrated Management System (IMS) in Power Plants?

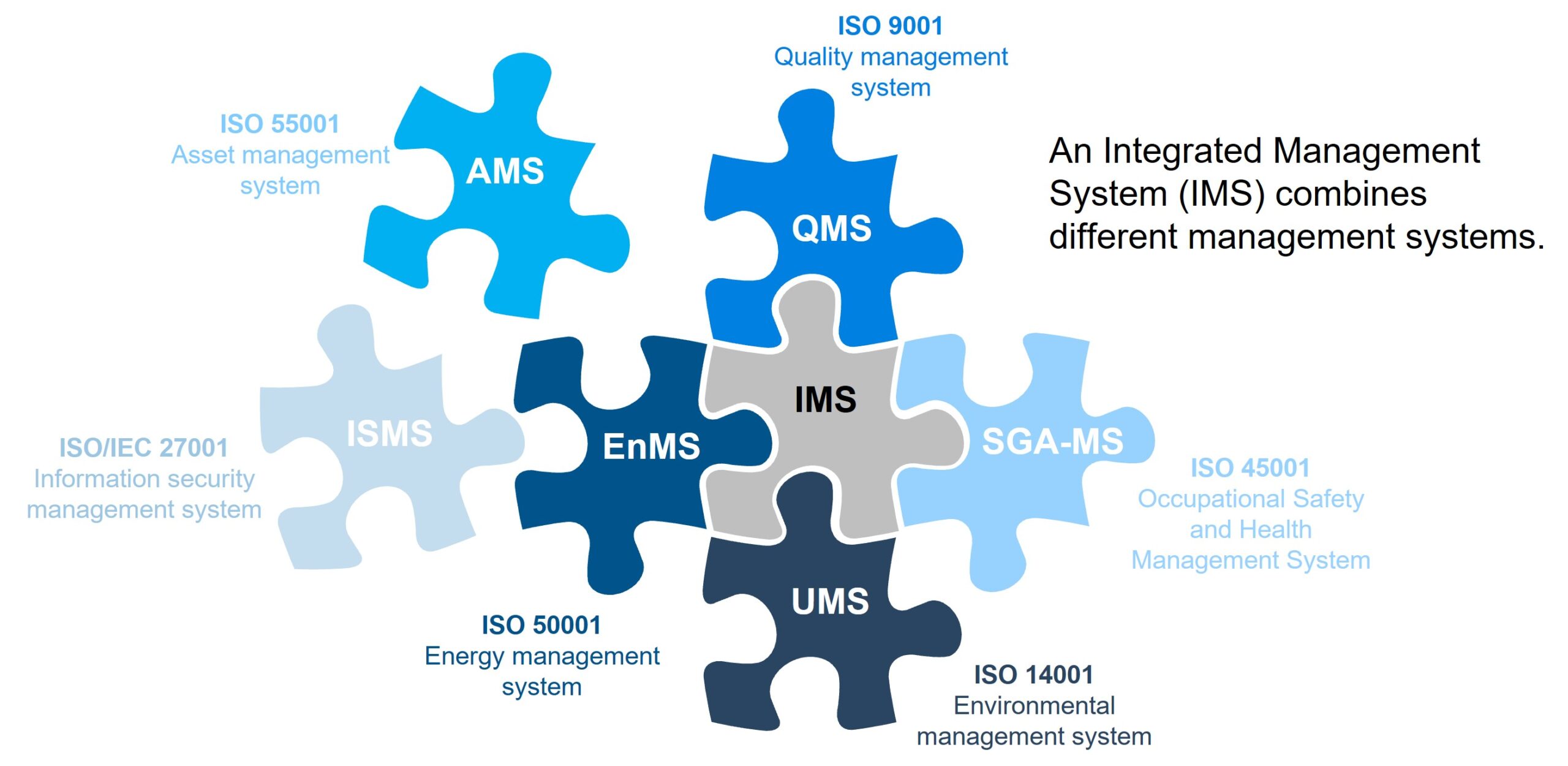

Power plants operate in high-risk environments with complex processes. To ensure operational excellence, safety, and environmental compliance, implementing IMS in power plants has become an industry best practice. An Integrated Management System (IMS) combines standards like ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health & Safety) into a unified framework.

This guide outlines a practical step-by-step approach for power plant operators and consultants looking to streamline operations, improve compliance, and drive sustainable growth.

Step 1: Management Commitment and Strategic Planning

IMS implementation begins at the top management level. Leadership must fully commit to:

- Aligning IMS goals with organizational objectives

- Allocating necessary resources

- Establishing roles and responsibilities

- Ensuring worker participation at all levels

In the power sector, where risks are high and regulations are stringent, this commitment is essential to drive successful implementation and long-term improvement.

Step 2: Conducting a Gap Analysis

A gap analysis helps assess the current system against the requirements of ISO 9001, ISO 14001, and ISO 45001. The focus should be on:

- Identifying missing policies and procedures

- Highlighting non-compliance with regulatory requirements

- Mapping existing controls and identifying overlaps

The findings will inform a detailed implementation roadmap for the IMS.

“Our IMS implementation services are tailored specifically for power plants across Pakistan“

Step 3: Define IMS Scope and Context of the Organization

Understanding the context of the power plant is crucial. This includes:

- External and internal issues affecting operations

- Stakeholder expectations (regulators, workers, public)

- Plant location, environmental impact zones, and safety-critical areas

Defining a clear scope helps ensure that the IMS is tailored to the plant’s specific risks and operational needs.

Step 4: Risk Assessment and Opportunity Identification

Each ISO standard emphasizes risk-based thinking. In power plants, this means:

- Identifying operational hazards (e.g. boiler pressure, high voltage)

- Assessing environmental risks (e.g. emissions, fuel spills)

- Evaluating quality risks (e.g. poor maintenance, downtime)

- Establishing mitigation and emergency response plans

Opportunities for improvement—like automation, energy efficiency, or waste reduction—should also be identified and prioritized.

Step 5: Integration of Processes, Documentation, and Controls

Integrate the following key elements into one IMS framework:

- Unified policy and objectives for quality, environment, and safety

- Common procedures (document control, audits, training)

- Shared risk registers and corrective action systems

- Centralized documentation and management review protocols

Using integrated controls reduces duplication and increases operational efficiency.

Step 6: Training and Awareness Programs

Staff at all levels must be trained on:

- IMS policies and objectives

- Reporting incidents and near-misses

- Emergency procedures

- Their roles in maintaining compliance

A robust training plan builds a culture of accountability and safety, especially in hazardous environments like power plants.

Step 7: Internal Audits and Management Review

Regular internal audits are essential to evaluate system performance and identify non-conformities. Management reviews should:

- Analyze audit findings

- Review key performance indicators (KPIs)

- Track legal compliance and customer satisfaction

- Approve continual improvement plans

This cycle strengthens governance and ensures the IMS remains aligned with evolving needs.

Step 8: Certification and Continuous Improvement

Once the system is mature, engage with accredited certification bodies for audits. Achieving ISO certification provides:

- External validation of operational excellence

- Competitive advantage in tenders and contracts

- Enhanced reputation with regulators and investors

After certification, the focus should shift to continuous improvement. Conduct root cause analysis, implement preventive actions, and monitor trends in safety, emissions, and reliability.

Implementing IMS in power plants is a strategic move that enhances compliance, sustainability, and safety in one unified framework.

Benefits of Implementing IMS in Power Plants

- Streamlined processes through reduced duplication

- Improved safety performance and reduced workplace accidents

- Enhanced environmental compliance and reduced pollution

- Consistent quality output through standardized processes

- Regulatory readiness and better documentation

- Stakeholder confidence through transparent governance

Final Thoughts

Implementing IMS in power plants is more than a compliance exercise—it’s a strategic initiative that improves operational efficiency, employee safety, and environmental performance. By integrating ISO 9001, ISO 14001, and ISO 45001 into a single system, power plants can meet global standards, drive continual improvement, and ensure long-term sustainability in a competitive energy sector.

Organizations often realize significant efficiency and risk reduction by implementing IMS in power plants, streamlining management processes across departments.